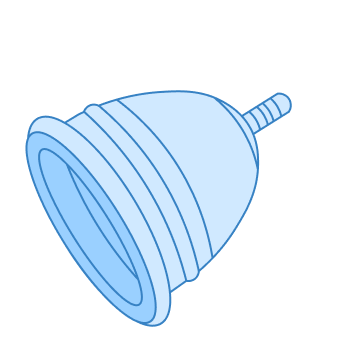

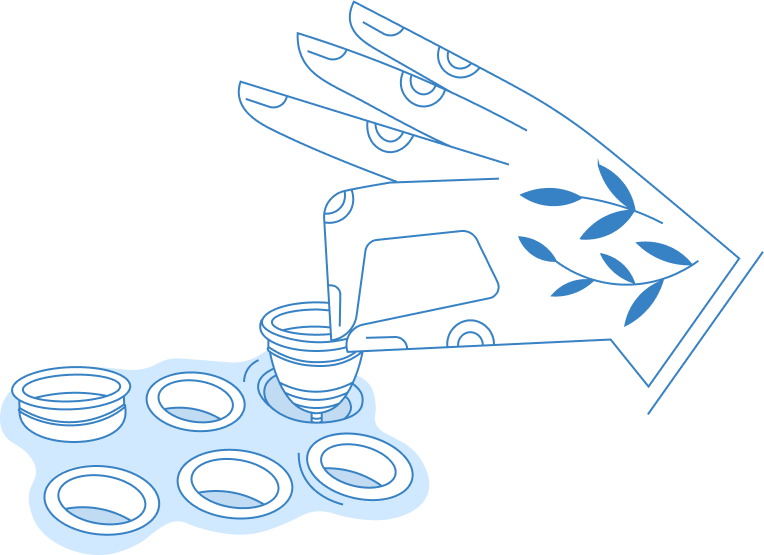

From Design to Dispatch, Crafted with Care

At

Crescenzia, we follow a meticulously planned manufacturing process to produce high-quality

menstrual cups. From raw material sourcing to packaging, we ensure that every step is

executed with precision, quality, and attention to detail. Here’s a breakdown of our

process:

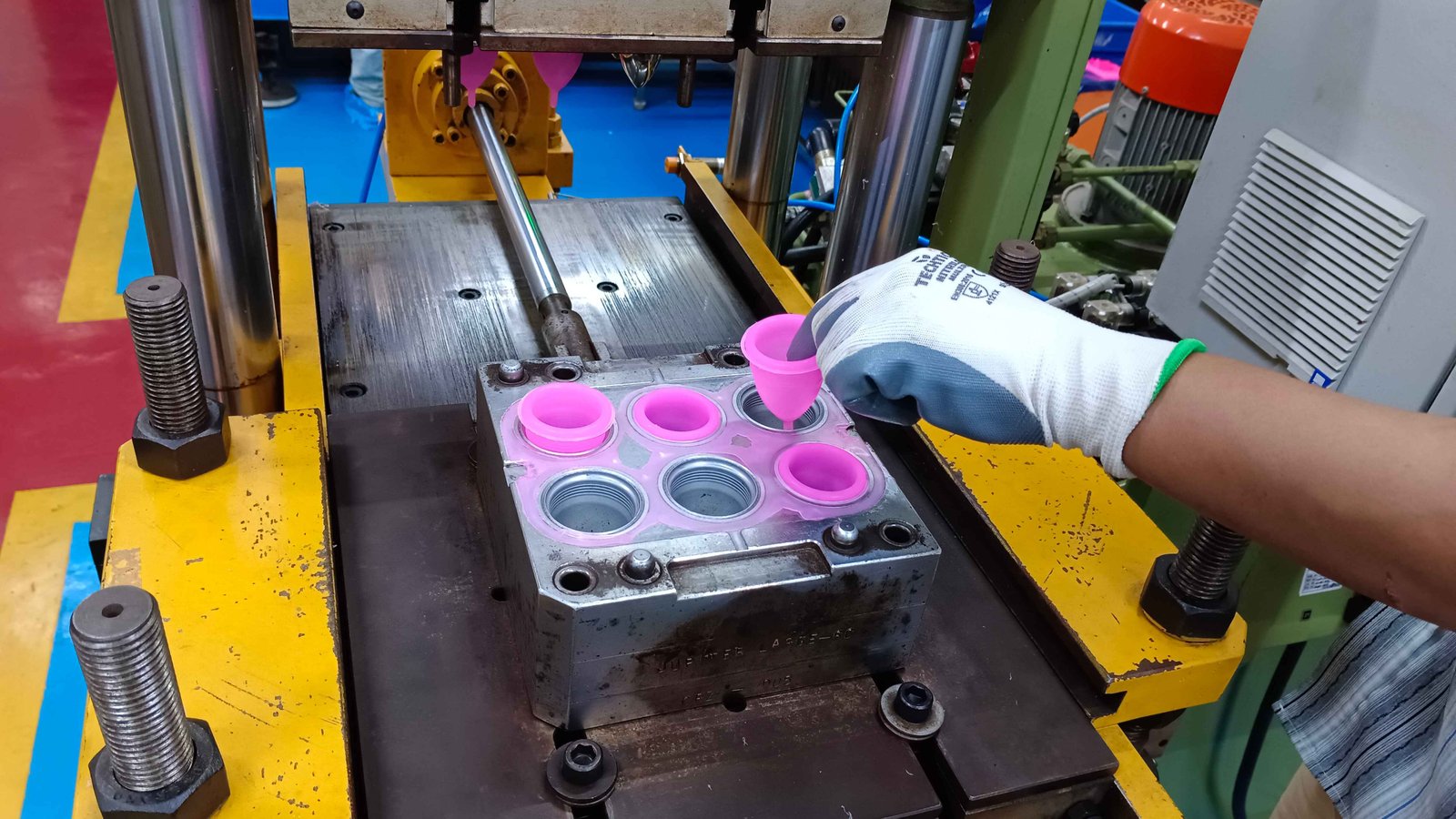

Our manufacturing unit is located in Electronic City, Bangalore, and is equipped with cutting-edge technology that supports efficient production, scalability, and flexibility. The unit adheres to global standards, and our skilled team works tirelessly to ensure that each product we create is safe, high-quality, and customer-ready.

At Crescenzia Wellness Pvt Ltd, we’re committed to helping you create high-quality menstrual cups that your customers can trust. Whether you're a distributor, a brand owner, or working on a government initiative, our manufacturing unit is here to support your needs.

At Crescenzia, we follow a meticulously planned manufacturing process to produce high-quality menstrual cups. From raw material sourcing to packaging, we ensure that every step is executed with precision, quality, and attention to detail. Here’s a breakdown of our process: